AUTOMATIC OPENER

What is an Automatic Opener?

An automatic opener is equipment designed to prevent the dispersion of powder particles and exposure to operators by automatically supplying and transporting POWDER BAGs and dispensing their contents without direct manipulation. When operators manually open a POWDER BAG, safety accidents caused by powder dispersion can be prevented. As an UNMANNED SYSTEM, the automatic opener operates without operator intervention or interference, and there are two types: one for opening TON BAGs and another for opening PAPER BAGs.

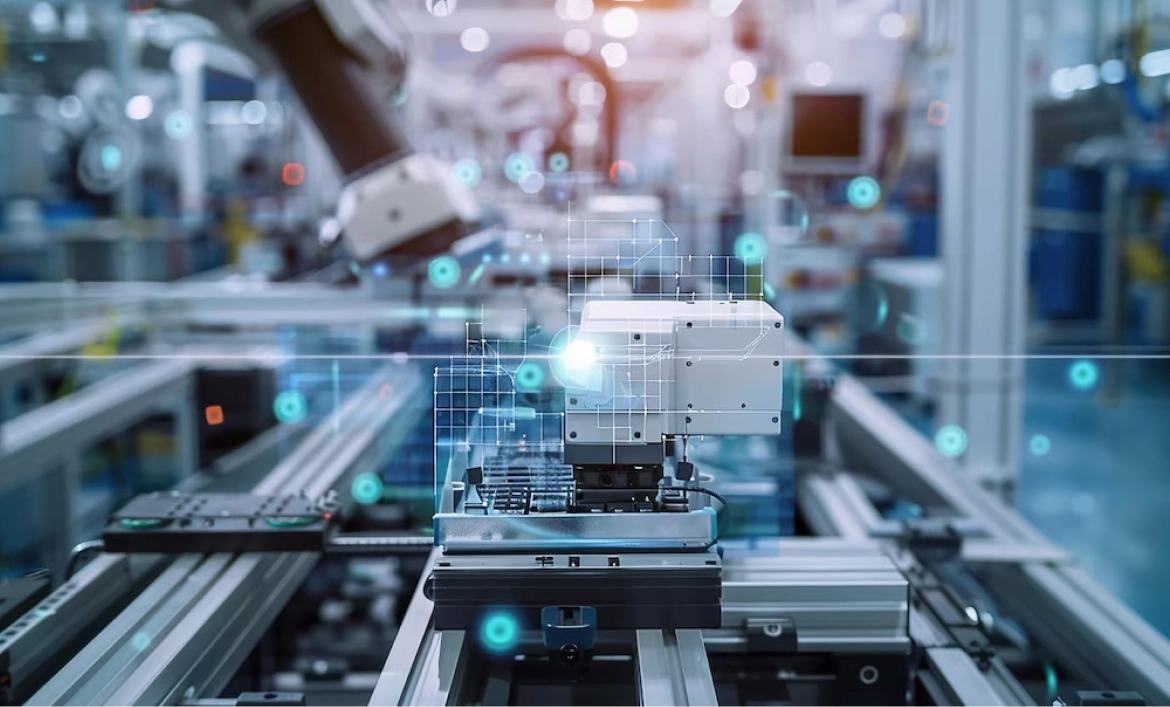

Composition and Principle of the Automatic Opener

Generally, an automatic opener consists of sensors, motors, and a control system. The sensors detect when a powder bag arrives at a specific position, and the motor receives this signal to perform the function of opening or closing the bag. The control system manages and controls the sequence of the operational process. The components of the automatic opener perform these processes quickly and accurately, thereby enhancing work efficiency.

Role of the Automatic Opener

The automatic opener automatically opens powder materials such as cathode materials, anode materials, and electrolytes, which are main components of secondary batteries, and safely transports them within a sealed system. This prevents additional contamination, preemptively mitigates hazardous tasks for operators, and ensures safety.

The automatic opener measures the precise amount of powder and supplies it to the mixing process, which is crucial as it directly affects battery performance. Consistent measurement and supply of quantities are key.

By automating the workflow, the automatic opener increases production speed and reduces operator errors, thereby maximizing the overall efficiency of the manufacturing process.

Operating Methods by Type of Automatic Opener

For PAPER BAG Opening

After positioning the PAPER BAG on the RAIL, it is transported into the AUTOMATIC BAG SLITTER MACHINE, and the CUTTING SYSTEM cuts both sides to open the PAPER BAG. Through VACUUM, the contents are transported and stored in the STORAGE HOPPER without dust.

For TON BAG Opening

A HOIST transports the TON BAG to the designated upper part of the CUTTING SYSTEM, where it is automatically opened by the CUTTING SYSTEM. Through VACUUM, the contents are transported and stored in the STORAGE HOPPER without dust.

Advantages of the Automatic Opener

The automatic opener is versatile equipment that combines convenience, efficiency, and safety, developed with non-dust characteristics in mind. It offers advantages of being faster and more convenient than traditional manual cutting methods and promotes safer operations.

Specific advantages of the automatic opener include:

Specific advantages of the automatic opener include:

Time Savings

By using an automatic opener, a significant portion of the operational time can be saved compared to manually opening and closing powder bags by operators. This time reduction effectively increases product production speed and reduces labor and input costs.

Enhancing Safety

Powder materials often contain airborne substances or allergens. The automatic opener prevents direct contact by operators, protecting them from contact allergies or diseases.

Minimal Powder Loss

The automatic opener opens and closes bags at a consistent speed and force, minimizing powder loss and ensuring accurate transfer quantities.

Efficient Operation Control

By using an automatic opener, a significant portion of the operational time can be saved compared to manually opening and closing powder bags by operators. This time reduction effectively increases product production speed and reduces labor and input costs.

Modular Design

With a modular design capable of accommodating various sizes and shapes of powder bags, availability is increased. This also allows easy application to different powder materials.

Remote Monitoring and Control

Modern automatic openers are integrated with IoT technology, enabling remote monitoring and control. They provide real-time inspection and recording of operating conditions or abnormalities, offering data analysis and feedback to improve the production process.

Future Development of the Automatic Opener

The functional development of automatic openers will advance through various AI technologies, specialized design techniques, and the development of controllable integrated systems.

Smart systems utilizing AI and machine learning technologies will analyze the characteristics of raw materials and mixing conditions, proposing optimal opening and mixing processes. This will further enhance production efficiency. In the future, automatic openers will evolve to use eco-friendly materials and be designed with energy efficiency in mind, allowing for more optimized operations in sustainable and continuous processes.

Additionally, more sophisticated sensor technologies will be introduced to monitor the state of powder, humidity, and temperature in real-time, enabling more detailed quality control and reducing defect rates. Lastly, solutions for managing the entire manufacturing process by integrating automatic openers with mixers and packaging systems are planned. These technological developments will broaden the utilization of automatic openers.

Smart systems utilizing AI and machine learning technologies will analyze the characteristics of raw materials and mixing conditions, proposing optimal opening and mixing processes. This will further enhance production efficiency. In the future, automatic openers will evolve to use eco-friendly materials and be designed with energy efficiency in mind, allowing for more optimized operations in sustainable and continuous processes.

Additionally, more sophisticated sensor technologies will be introduced to monitor the state of powder, humidity, and temperature in real-time, enabling more detailed quality control and reducing defect rates. Lastly, solutions for managing the entire manufacturing process by integrating automatic openers with mixers and packaging systems are planned. These technological developments will broaden the utilization of automatic openers.

The automatic opener in the powder mixing process provides a safe and efficient production environment and has an important impact on battery performance. The introduction of the automatic switchboard has increased production efficiency, strengthened worker safety, and enabled accurate handling of raw materials.

In the future, automatic switchgear will continue to develop in conjunction with the latest technologies such as AI and IoT, and will lead to innovation in detailed processes. These developments are expected to become an essential factor in responding to the growing demand for secondary batteries in various fields such as electric vehicles and energy storage systems.

In the future, automatic switchgear will continue to develop in conjunction with the latest technologies such as AI and IoT, and will lead to innovation in detailed processes. These developments are expected to become an essential factor in responding to the growing demand for secondary batteries in various fields such as electric vehicles and energy storage systems.